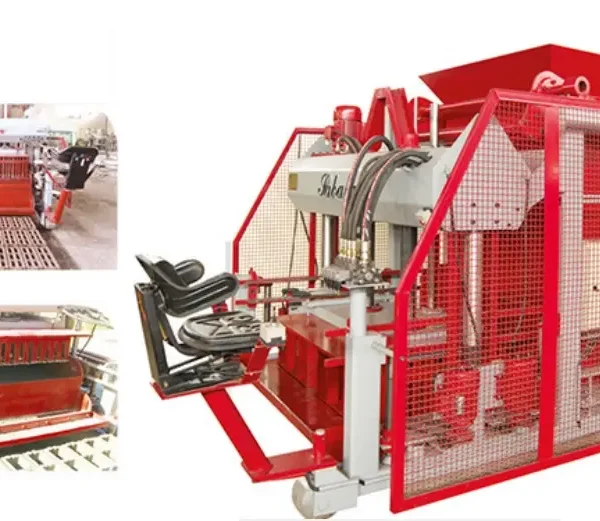

S20 model three-row fully automatic moving block machine was designed and implemented for the first time by Sablan Tabriz company. This machine is suitable for producing all kinds of roof, wall and blade blocks and all kinds of bricks with all kinds of sand and sand, pumice, and lika materials. The S20 fully automatic block machine system has a silo and the silo is not fed with concrete manually. Silo capacity It is suitable for producing 150 blocks. In addition, a filling system is installed inside the cart of the machine, which increases the production speed and quality of the produced block and reduces the wear of the machine. The mold and matrix (shoulder) are moved by jacks. This machine is fully automatic and all parts including the mold system, feeding system and movement and rotation in the production line are fully automatic. In this system, manpower has a very small role and it is possible to produce all kinds of blocks through one specialized workforce.

The S20 mobile block making machine has a steering wheel, 18-27 blocks of 20 (each course has the ability to produce 18-27 blocks of 20), four hydraulic vibrators that vibrate simultaneously with the hydraulic press from above.

The S20 machine has a separate electric motor for the steering wheel for the convenience of turning the machine and a 4 kw electric motor for the automatic movement of the blocking machine.

The ability to produce bricks, the ability to produce all kinds of blocks, equipped with an automatic breaker, hydraulic system with 5 levers, the machine moves automatically, equipped with a four-way oil vertical vibrator, with the feature of uniform filling, with a cart for carrying mortar on the mold

The alternator of the S20 device is as follows One 10 HP dynamo for the hydraulic system, four 3 HP dynamo for the vibration system, one 2 HP dynamo for the automatic bypass system, one 1.5 kW dynamo for the filling system, one 4 kW dynamo for the movement system, one 1.5 kW dynamo for the system