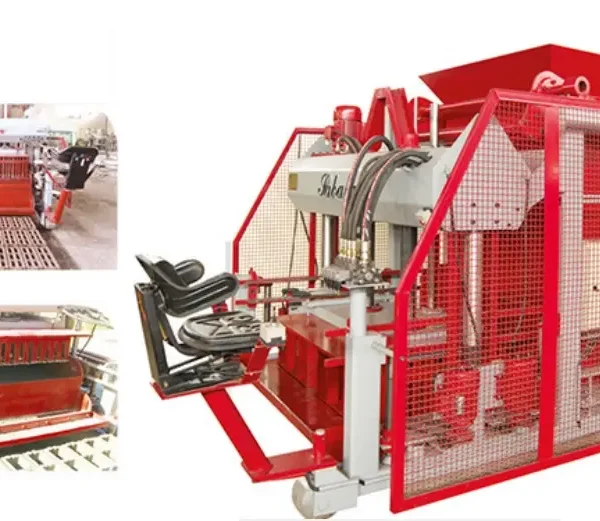

The latest and most up-to-date technology in the world in the production of tables and flooring using the wet concrete method, the wet press machine

The single-station wet press machine is the latest technology in the field of producing concrete tables and floors, which Sablan Tabriz factory complex has removed its technology from the monopoly of England and Germany.

The wet press machine is the best method of producing tables from wet concrete by the vacuum system in order to drain the water quickly and without errors from the produced product, and the tables produced by the wet press are durable and have a long life. This machine has the ability to produce tables and floor coverings with dimensions of at least 400*400*50 and at most 500*1000 mm fully automatically and manually.

Sablan Tabriz Wet Press Company is producing and operating in two modes, single-station and three-station

A factory for the production of concrete parts using the wet dense method

Wet press mother machine: the chassis of the machine is made of single-frame steel so that it can easily withstand the pressure of 1000 tons. It has a press power of more than 700 tons and its hydraulic powerpack system is in the form of a block based on the latest technology in the world. Hydraulics is made. It has the ability to produce two tables of 50 x 50 cm at the same time. The material of the molds of this machine is selected from anti-wear hardox alloy steel. The coils of the mold are selected from a sheet of fabric without welding. For the first time in the world, this device is equipped with fabric and paper filter technology

The part-picking robot of the wet press machine: The pressed part is removed by the smart robot and the job of the robot is to transfer the production from the station of the mother device to the conveyor, which rotates the production by 90 degrees and turns it from a lying position to a standing position due to the ease of moving and occupying less space.

The output conveyor of the wet press machine: The conveyor arranges 7 tables with maximum dimensions of 100×50 cm or 14 tables of 50×50 cm and guides them on a metal pallet in a fully automatic manner.